Foothills Steel Foundry Crusher Wear Parts Foothills ...

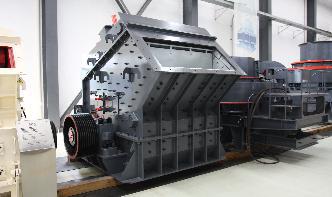

Foothills Steel Foundry are renowned for high quality wear parts for the crushing industry – its what we do best. Our product range includes a large catalogue of crusher wear liners, covering most commonly used crushers. We have stock of Jaw, Cone and Impact crusher liners in stock in our warehouse at all times, covering most common crusher brands.